In the realm of packaging, achieving a secure and tamper-evident seal is crucial for maintaining product integrity and consumer trust. Handheld induction sealers are an excellent solution for businesses and laboratories that require a portable, easy-to-use, and cost-effective sealing option. This guide will explore everything you need to know about handheld induction sealers, including their functionality, applications, benefits, and tips for choosing the right model for your needs.

What is a Handheld Induction Sealer?

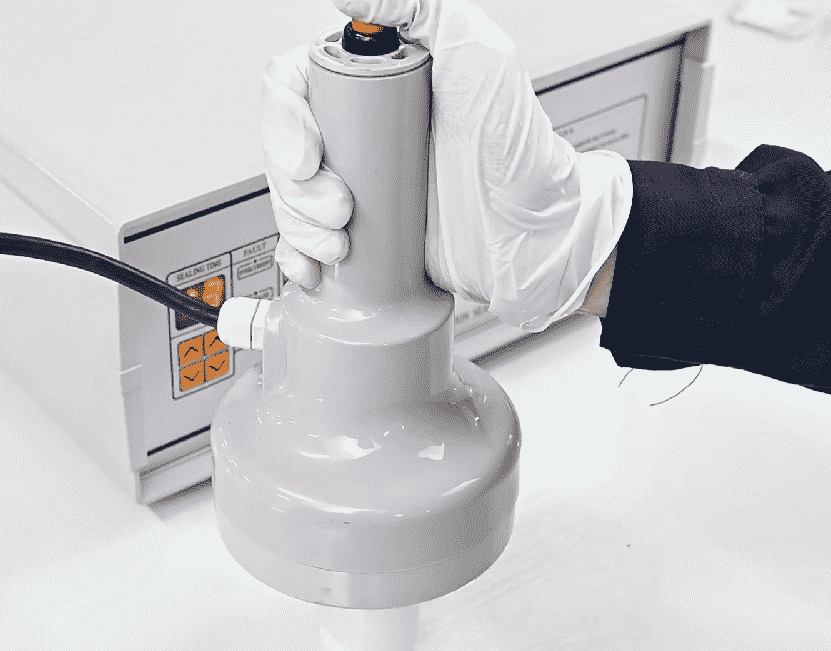

A handheld induction sealer is a compact, portable device designed to seal containers with foil liners using electromagnetic induction. This process ensures an airtight, tamper-evident seal that helps preserve product freshness and prevent contamination. Handheld induction sealers are ideal for small-scale operations, laboratories, and businesses with moderate production needs.

How Does a Handheld Induction Sealer Work?

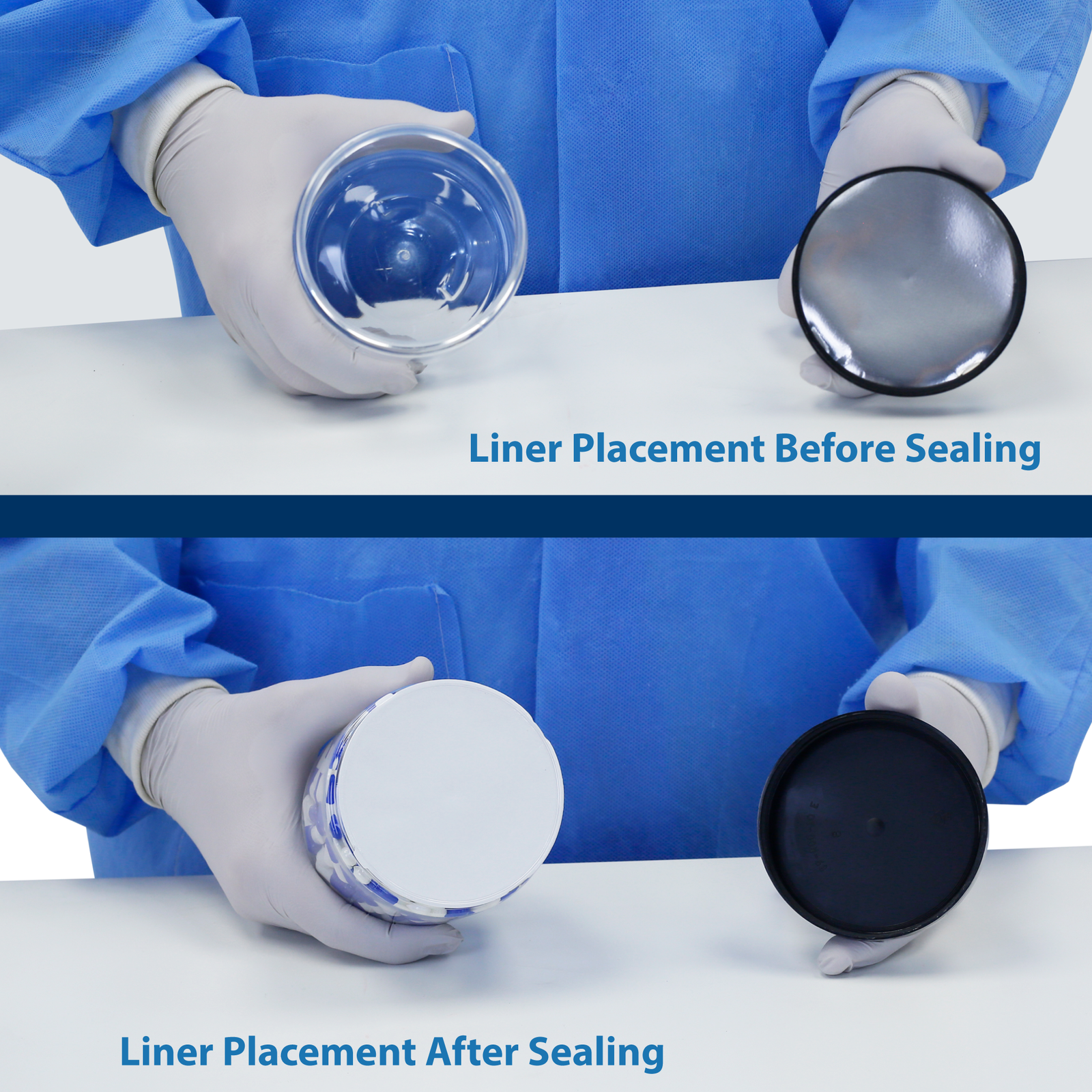

- Container Placement: The container, fitted with a foil-lined cap or seal, is positioned under the sealing head of the handheld induction sealer.

- Induction Heating: The machine generates an electromagnetic field that induces an electric current in the foil liner.

- Sealing Process: The electric current heats the foil liner, melting the sealant layer and bonding it to the container’s rim.

- Cooling and Completion: Once the sealant cools, it forms a secure, airtight seal. The container can then be handled normally.

Key Features of Handheld Induction Sealers

- Portability: Lightweight and easy to transport, making them ideal for on-the-go sealing needs.

- Ease of Use: Simple operation, often requiring just the push of a button to create a seal.

- Adjustable Power: Power settings can be adjusted to accommodate different container sizes and materials.

- Cost-Effective: Lower cost compared to larger, automated machines, making them accessible for smaller businesses and laboratories.

- Versatility: Suitable for a wide range of container types and sizes, from small bottles to larger jars.

Applications of Handheld Induction Sealers

- Food and Beverage: Seals containers of liquids, powders, and granules to ensure freshness and prevent contamination.

- Pharmaceuticals: Provides tamper-evident seals for medicines, supplements, and other healthcare products.

- Cosmetics: Seals bottles and jars of creams, lotions, and other personal care products to maintain product integrity.

- Chemical Products: Ensures leak-proof seals for containers of various chemicals.

- Laboratories: Ideal for research and development settings where flexibility and portability are needed.

Benefits of Using Handheld Induction Sealers

- Enhanced Product Safety: Provides tamper-evident and leak-proof seals, ensuring product integrity and consumer safety.

- Extended Shelf Life: Creates airtight seals that preserve the freshness and quality of perishable products.

- Flexibility: Can be easily moved and used in different locations, ideal for on-site sealing needs.

- User-Friendly: Simple and intuitive operation, requiring minimal training for effective use.

- Cost Savings: Affordable initial investment with low maintenance costs, making it a budget-friendly option for small businesses.

How to Choose the Right Handheld Induction Sealer

When selecting a handheld induction sealer, consider the following factors:

- Production Volume: Ensure the machine can handle your expected production volume. Handheld sealers are best suited for small to moderate production needs.

- Container Compatibility: Verify that the sealer is compatible with the types and sizes of containers you use.

- Power and Efficiency: Choose a machine with adjustable power settings to accommodate different sealing requirements.

- User Interface: Look for a model with an intuitive and easy-to-use interface.

- Budget: Consider your budget and ensure the chosen model offers the best balance of features and cost-effectiveness.

Maintenance and Care Tips

- Regular Cleaning: Keep the sealing head and other components clean to prevent residue buildup and ensure optimal performance.

- Check for Wear: Inspect the sealing head and power supply for signs of wear and replace parts as needed.

- Calibration: Periodically check the calibration of the machine to ensure consistent sealing quality.

- Proper Storage: Store the sealer in a clean, dry environment to protect it from dust and moisture.

Conclusion

Handheld induction sealers are invaluable tools for businesses and laboratories that require flexible, portable, and efficient sealing solutions. Their ability to create tamper-evident, airtight seals makes them ideal for a variety of applications, from food and beverages to pharmaceuticals and cosmetics. By understanding their functionality, features, and maintenance requirements, you can leverage handheld induction sealers to enhance your packaging operations, improve product safety, and extend shelf life.

Investing in a high-quality handheld induction sealer can significantly benefit your business, offering unmatched versatility, ease of use, and cost-effectiveness. Whether you’re a small business owner, a laboratory technician, or a specialty product manufacturer, a handheld induction sealer provides a reliable and efficient solution for all your sealing needs.