Servo Motors

Introduction

Servo motors are essential components in many precision control systems, widely used in robotics, manufacturing, and various automation applications. Understanding the principles and applications of servo motors can enhance the design and functionality of these systems. This guide provides an in-depth look at the working principles of servo motors and explores their diverse applications, offering valuable insights for engineers, technicians, and hobbyists.

What is a Servo Motor?

A servo motor is a rotary actuator or linear actuator that enables precise control of angular or linear position, velocity, and acceleration. It consists of a suitable motor coupled to a sensor for position feedback. Servo motors are controlled by sending a pulse-width modulation (PWM) signal to the motor’s controller.

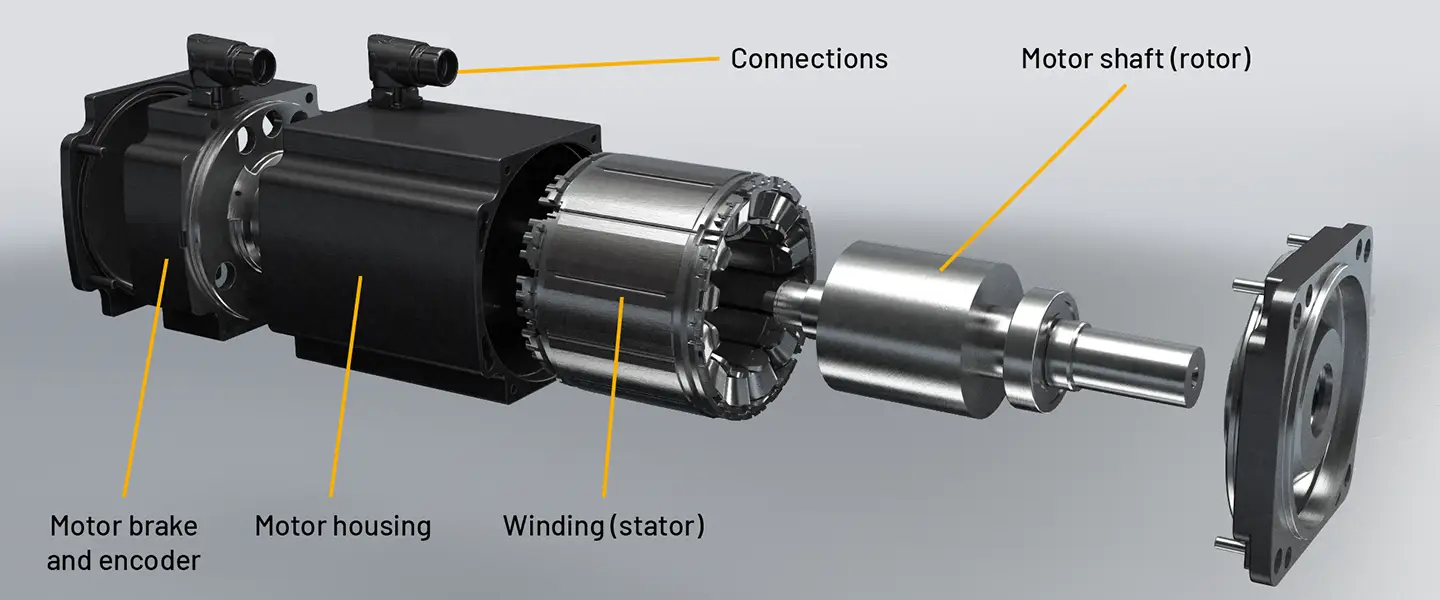

Components of a Servo Motors:

A servo motor comprises several key components, including:

- Motor: The heart of the servo system, typically a DC motor or AC motor.

- Feedback Device: Provides positional feedback to the control system, allowing for accurate positioning.

- Control System: Processes the feedback signal and generates appropriate commands to the motor.

- Gearing: Often included to increase torque output and reduce the speed of rotation.

- Driver Circuitry: Amplifies and modulates the control signals to drive the motor efficiently.

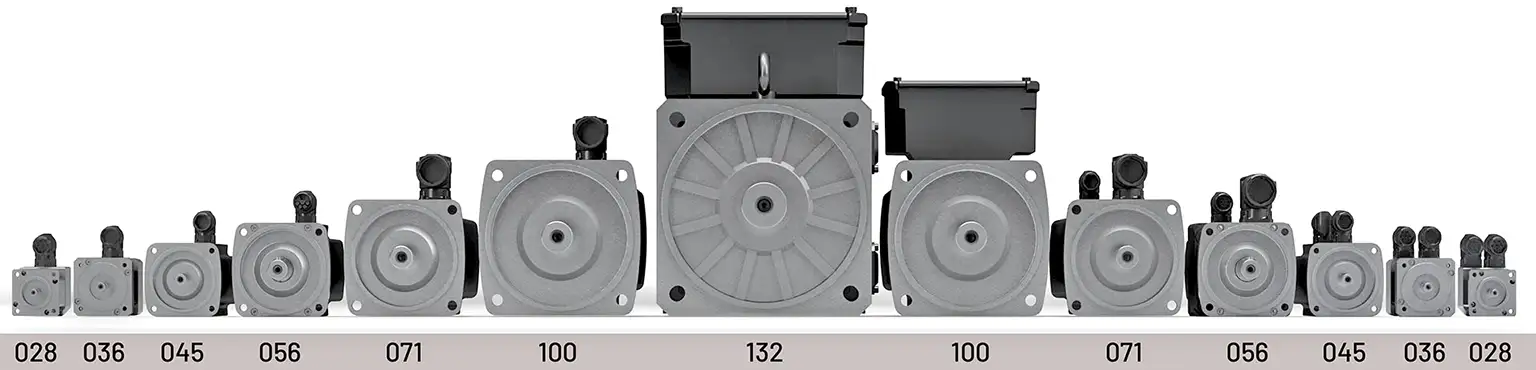

Types of Servo Motors

-

DC Servo Motors

- Structure: These motors use brushes and a commutator for current conduction.

- Control: Simple and cost-effective to control.

- Advantages: Low cost, easy to control.

- Disadvantages: Brush wear, requiring regular maintenance, and lower efficiency.

- Applications: Low-cost, low-maintenance applications, basic automation, and hobbyist projects.

- Structure: Utilizes electronic commutation instead of brushes.

- Control: Requires more sophisticated control electronics.

- Advantages: Higher efficiency, lower maintenance, longer lifespan.

- Disadvantages: More complex control systems and higher initial cost.

- Applications: High-performance applications, robotics, industrial automation, and electric vehicles.

- Structure: Operates using alternating current (AC) and typically involves synchronous or asynchronous motors.

- Control: Advanced control systems, often using vector control or direct torque control.

- Advantages: High torque, robust, reliable, suitable for high-power applications.

- Disadvantages: More complex and costly control systems.

- Applications: Industrial machinery, robotics, CNC machinery, and high-precision applications.

3. Stepper Motors (Hybrid Servos)

- Structure: Operates in discrete steps, with multiple coils arranged in phases.

- Control: Stepwise control without feedback, can be used in closed-loop systems for higher accuracy.

- Advantages: High precision positioning, low cost, easy to control.

- Disadvantages: Less efficient at high speeds, can lose steps if overloaded without feedback.

- Applications: 3D printers, CNC machines, automated manufacturing, and precision positioning systems.

4. Linear Servo Motors

- Structure: Converts rotary motion into linear motion.

- Control: Similar control principles as rotary servo motors but designed for linear movement.

- Advantages: Direct linear motion without mechanical linkages, high precision.

- Disadvantages: More expensive and complex to design and control.

- Applications: High-precision linear motion applications, such as CNC machines and robotics.

5. Synchronous Servo Motors

- Structure: Operates synchronously with the frequency of the supply current.

- Control: Requires precise control of supply frequency and voltage.

- Advantages: High efficiency, precise control of speed and position.

- Disadvantages: Requires sophisticated control systems.

- Applications: High-precision applications, such as industrial automation and robotics.

Working Principle

Servo motors operate based on feedback control, typically involving the following components:

- Motor: Converts electrical energy into mechanical motion.

- Encoder: Provides feedback on the motor’s position, speed, and direction.

- Controller: Processes input commands and feedback signals to control the motor’s movement.

- Drive/Amplifier: Supplies power to the motor as per the controller’s commands.

The feedback loop allows the controller to compare the actual position of the motor with the desired position and make adjustments as needed to correct any errors.

Applications

- Robotics: Servo motors provide precise control of joint positions and movements.

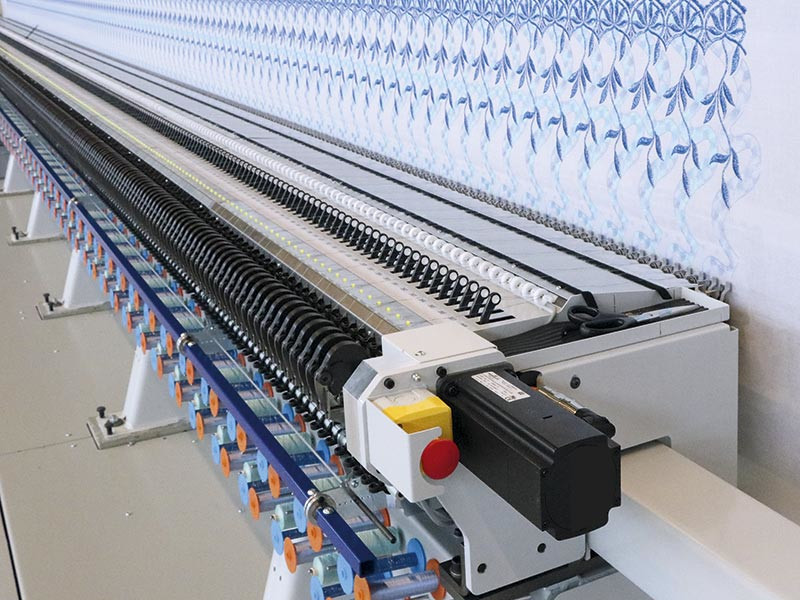

- CNC Machines: Used to control the position and speed of machine tool components.

- Industrial Automation: Integral to automated manufacturing systems for controlling conveyors, lifts, and other machinery.

- Aerospace: Used in control surfaces of aircraft for precise maneuvering.

- Consumer Electronics: Found in devices like cameras (for lens focusing) and DVD players (for disc loading mechanisms).

- Automotive: Utilized in systems like cruise control, electronic throttle control, and electric power steering.

Advantages

- Precision: Capable of high-precision control of angular or linear position.

- Speed: Can achieve high speeds with quick acceleration and deceleration.

- Efficiency: Brushless DC servo motor is particularly efficient.

- Reliability: High reliability and durability, especially in brushless types.

- Flexibility: Suitable for a wide range of applications from small hobby projects to large industrial machines.

Servo Motors Maintenance

Regular maintenance is crucial to ensure the optimal performance and longevity of servo motor. Here are some maintenance tips:

- Visual Inspection: Regularly inspect for any signs of wear, damage, or overheating.

- Cleaning: Keep the motor and surrounding areas clean from dust and debris.

- Lubrication: Apply lubrication to mechanical components as needed, following manufacturer recommendations.

- Electrical Checks: Verify insulation resistance and continuity of windings.

- Feedback System: Ensure the encoder or resolver is clean and functioning correctly.

- Connection Checks: Inspect and secure all electrical and mechanical connections.

Troubleshooting Common Issues

- Overheating: Ensure proper ventilation and cooling, check for overloading.

- Vibration: Check for misalignment, bearing wear, or loose mounting.

- Noise: Inspect for mechanical issues or electrical interference.

- Loss of Position: Verify the feedback system, inspect cables and connections, recalibrate if necessary.

- Alarms and Errors: Use diagnostic tools and consult the manufacturer’s documentation to identify and resolve specific error codes.

Conclusion

Servo motors are vital components in many modern applications due to their precision, efficiency, and reliability. Understanding the different types, working principles, and maintenance requirements of servo motors can help you select the right motor for your needs and ensure it operates efficiently over its lifespan. Regular inspection and maintenance are key to preventing issues and maximizing the performance of your servo systems.

FAQs

- What is the main difference between AC and DC servo motors?

- AC servo motors use alternating current and are generally more efficient and suitable for high-performance applications, while DC servo motors use direct current and are simpler to control.

- Can servo motors be used in high-speed applications?

- Yes, servo motors are capable of high-speed operation, but the choice of motor type and proper parameter settings are crucial for optimal performance.

- How do I choose the right servo motor for my application?

- Consider factors like required torque, speed, precision, operational environment, and budget. Consulting with manufacturers and referring to application-specific guidelines can also help.