Cap Sealers

In the realm of packaging, ensuring product integrity and safety is paramount. Cap sealers emerge as indispensable tools, offering tamper-evident and leak-proof seals for a wide range of containers. This comprehensive guide delves into everything you need to know about cap sealers, from their functionality to their applications and benefits.

Understanding Cap Sealers

Cap sealers, also known as cap induction sealers or cap sealing machines, are specialized devices designed to create airtight seals on containers with foil-lined caps or seals. These machines utilize electromagnetic induction to heat and seal the foil liner to the container’s rim, providing tamper-evident and leak-proof closures.

How Do Cap Sealers Work?

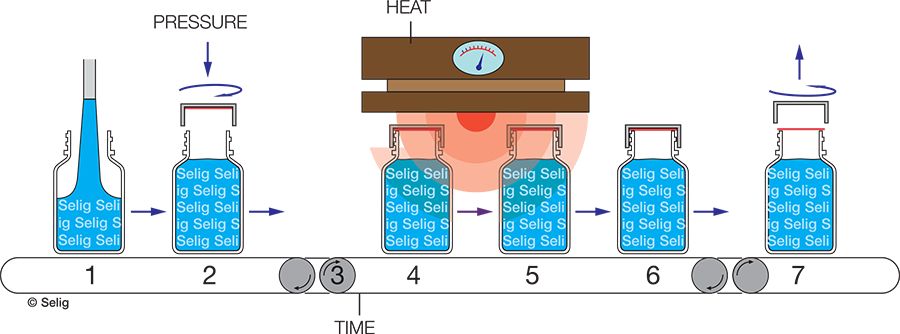

- Container Preparation: Containers with foil-lined caps or seals are placed under the sealing head of the cap sealer.

- Induction Heating: The sealer generates an electromagnetic field, inducing a current in the foil liner of the cap.

- Sealing Process: The induced current heats the foil liner, causing the sealant layer to melt and bond to the container’s rim.

- Cooling and Sealing: Once the sealant cools, it forms a secure, tamper-evident seal, ready for storage or shipment.

Key Features of Cap Sealers

- Versatility: Accommodates various container sizes and types, including bottles, jars, and containers made of plastic, glass, or metal.

- Adjustable Power Settings: Allows fine-tuning of sealing parameters to accommodate different container materials and sealing requirements.

- Digital Controls: Intuitive interface with digital displays for easy operation and monitoring.

- High Precision: Ensures consistent and reliable sealing for product integrity and consumer safety.

- Tamper-Evident Seals: Provides visible evidence of tampering, enhancing product security and consumer trust.

Applications of Cap Sealers

- Food and Beverage: Ensures freshness and prevents contamination in packaged goods such as sauces, condiments, and beverages.

- Pharmaceuticals: Provides tamper-evident seals for medicines, vitamins, and other healthcare products.

- Cosmetics: Maintains product integrity and prevents leakage in skincare, haircare, and beauty products.

- Chemicals: Ensures leak-proof seals for containers of various chemical products, including cleaning agents and industrial chemicals.

Benefits of Using Cap Sealers

- Enhanced Product Safety: Provides tamper-evident and leak-proof seals, ensuring product integrity and consumer confidence.

- Extended Shelf Life: Preserves the freshness and quality of packaged products, reducing spoilage and waste.

- Increased Efficiency: Streamlines the packaging process with fast and reliable sealing, improving overall productivity.

- Versatility: Accommodates a wide range of container sizes and materials, offering flexibility for different packaging needs.

- Cost-Effectiveness: Offers a cost-effective sealing solution compared to other methods, reducing packaging costs in the long run.

How to Choose the Right Cap Sealer

Consider the following factors when selecting a cap sealer:

- Production Volume: Ensure the machine can handle your expected production volumes effectively.

- Container Compatibility: Verify that the sealer is compatible with the sizes and types of containers you use.

- Power and Efficiency: Choose a model with adjustable power settings to accommodate different sealing requirements.

- User Interface: opt for a machine with an intuitive interface and digital controls for ease of operation.

- Budget: Evaluate your budget and select a model that offers the best balance of features and affordability.

Maintenance and Care Tips

- Regular Cleaning: Keep the sealing head and other components clean to prevent residue buildup and maintain optimal performance.

- Check for Wear: Inspect the machine regularly for signs of wear and replace parts as needed to ensure consistent sealing quality.

- Calibration: Periodically calibrate the machine to ensure accurate sealing parameters.

- Proper Storage: Store the sealer in a clean, dry environment to protect it from dust and moisture when not in use.

Conclusion

Cap sealers play a crucial role in ensuring product integrity, safety, and consumer trust across various industries. By understanding their functionality, features, and maintenance requirements, businesses can leverage cap sealers to enhance their packaging operations and preserve the quality of their products. Whether you’re in the food and beverage industry, pharmaceuticals, cosmetics, or chemicals, a cap sealer offers unmatched reliability and efficiency, helping you achieve your packaging goals with confidence.