Induction Sealer Machines

In the competitive world of packaging, ensuring product integrity and tamper-evidence is crucial. Induction sealer machines have become a vital tool in achieving these goals across various industries. These machines use electromagnetic induction to seal containers with foil liners, providing a secure and airtight seal. This comprehensive guide explores everything you need to know about induction sealer machines, from their functionality to their applications.

What is an Induction Sealer Machine?

An induction sealer machine is a device that uses electromagnetic induction to heat and seal a foil liner to the opening of a container. This process creates a hermetic seal that is tamper-evident, leak-proof, and preserves product freshness. Induction sealers are widely used in the food and beverage, pharmaceutical, chemical, and cosmetic industries.

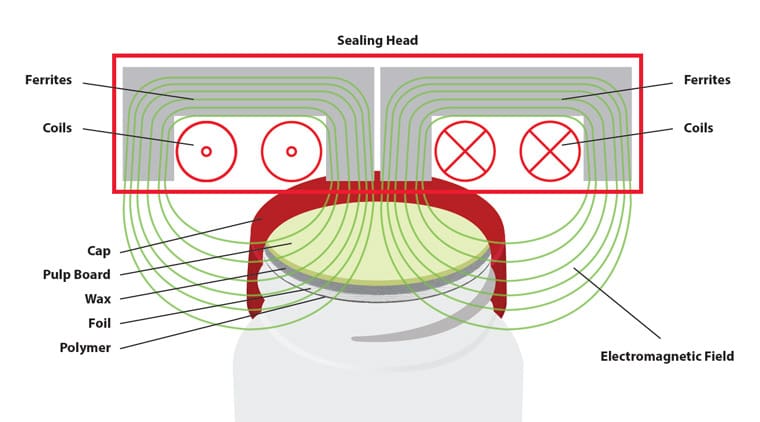

How Does an Induction Sealer Machine Work?

- Container Placement: A container with a foil-lined cap or seal is placed under the induction sealing head.

- Electromagnetic Induction: The machine generates an electromagnetic field that induces an electric current in the foil liner.

- Heating Process: The electric current heats the foil liner, melting the sealant layer and bonding it to the container’s rim.

- Cooling and Sealing: Once the sealant layer cools, it forms a secure, airtight seal that adheres to the container’s rim.

Components of an Induction Sealer Machine:

- Power Supply: The heart of the induction sealer, providing the necessary energy to generate the electromagnetic field.

- Induction Coil: This coil generates the electromagnetic field, which heats the foil seal.

- Control Panel: Allows operators to adjust settings such as power output, conveyor speed, and sealing time.

- Conveyor System: Transports containers through the induction field at a consistent speed for uniform sealing.

- Cooling System: Prevents overheating and ensures continuous operation.

Key Features of Induction Sealer Machines

- Electromagnetic Field: Utilizes an electromagnetic field to induce heat in the foil liner, ensuring a consistent and reliable seal.

- Adjustable Power Settings: Offers adjustable power levels to accommodate different container sizes, materials, and sealing requirements.

- Versatile Sealing Heads: Equipped with interchangeable sealing heads to handle various container shapes and sizes.

- Tamper-Evident Seals: Provides tamper-evident and leak-proof seals, enhancing product safety and integrity.

- User-Friendly Interface: Features intuitive controls and digital displays for easy operation and monitoring

Applications of Induction Sealer Machines

- Food and Beverage: Seals containers of liquids, powders, and granules to ensure freshness and prevent contamination.

- Pharmaceuticals: Provides tamper-evident seals for medicines, supplements, and other healthcare products.

- Chemicals: Ensures leak-proof seals for containers of hazardous and non-hazardous chemicals.

- Cosmetics: Seals bottles and jars of creams, lotions, and other personal care products to maintain product integrity.

- Agricultural Products: Seals containers of seeds, fertilizers, and other agricultural goods to protect against moisture and contamination.

Benefits of Using Induction Sealer Machines

- Enhanced Product Safety: Provides tamper-evident and leak-proof seals, ensuring product integrity and consumer safety.

- Extended Shelf Life: Creates airtight seals that preserve the freshness and quality of perishable products.

- Cost-Effective: Reduces the risk of product recalls and returns due to contamination or leakage.

- Increased Efficiency: Offers fast and reliable sealing, enhancing production line efficiency and throughput.

- Versatility: Suitable for a wide range of container materials, including plastic, glass, and metal.

Types of Induction Sealer Machines

- Handheld Induction Sealers: Portable and easy to use, ideal for small-scale operations and laboratory settings.

- Bench-Top Induction Sealers: Compact and versatile, suitable for medium-sized production runs and various container sizes.

- Inline Induction Sealers: Integrated into production lines for high-speed, continuous sealing operations in large-scale manufacturing.

- Cap Induction Sealers: Cap induction sealers are specialized machines designed to seal containers without caps. They are often used for sealing foil liners directly to the container’s rim before the cap is applied.

How to Choose the Right Induction Sealer Machine

When selecting an induction sealer machine, consider the following factors:

- Production Volume: Choose a machine that meets your production volume requirements, whether small-scale or high-speed operations.

- Container Compatibility: Ensure the machine is compatible with the types and sizes of containers you use.

- Power and Efficiency: Select a machine with adjustable power settings to accommodate different sealing needs and maximize efficiency.

- User Interface: Look for a machine with an intuitive interface and digital controls for easy operation and monitoring.

- Budget: Consider your budget and choose a machine that offers the best balance of features and cost-effectiveness.

Maintenance and Care Tips

- Regular Cleaning: Clean the sealing head and other components regularly to prevent residue buildup and ensure optimal performance.

- Check for Wear: Inspect the sealing head and power supply for signs of wear and replace parts as needed to maintain efficiency.

- Calibration: Regularly calibrate the machine to ensure consistent sealing quality and performance.

- Proper Storage: Store the machine in a clean, dry environment to protect it from dust and moisture.

Conclusion

Induction sealer machines are essential tools for businesses that require reliable, tamper-evident, and airtight packaging solutions. Their ability to create secure seals through electromagnetic induction makes them ideal for a wide range of industries, from food and beverage to pharmaceuticals and cosmetics. By understanding their functionality, features, and maintenance requirements, you can leverage induction sealer machines to enhance your packaging operations, improve product safety, and increase efficiency.

Investing in a high-quality induction sealer machine can transform your packaging process, providing peace of mind that your products are securely sealed and protected. Whether you’re a small business owner, a large-scale manufacturer, or a laboratory technician, an induction sealer machine offers unmatched reliability, versatility, and performance for all your sealing needs.