Horizontal Continuous Heat Sealers

In the world of packaging, the efficiency and reliability of sealing equipment are paramount. Horizontal continuous heat sealers are at the forefront of advanced packaging solutions, offering unparalleled speed and consistency for sealing thermoplastic materials. Whether you’re a large-scale manufacturer or a small business, understanding the capabilities and benefits of these machines can greatly enhance your packaging operations. This guide covers everything you need to know about horizontal continuous heat sealers.

What is a Horizontal Continuous Heat Sealer?

A horizontal continuous heat sealer is a type of sealing machine designed for high-speed, automated sealing of plastic bags and other thermoplastic materials. Unlike impulse sealers, which apply heat intermittently, continuous heat sealers maintain a constant temperature, allowing for continuous operation and faster sealing processes. These machines are typically used in industrial and commercial settings where high throughput is essential.

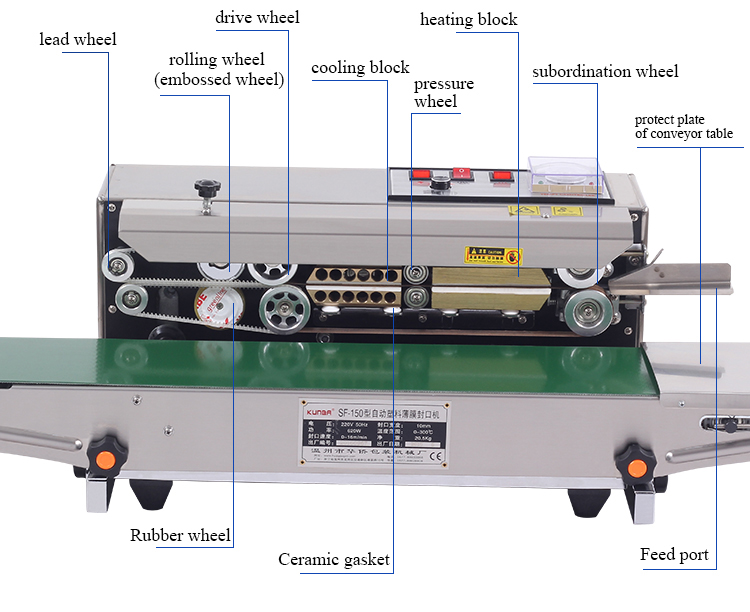

How Does a Horizontal Continuous Heat Sealer Work?

- Constant Heat: The sealer maintains a steady temperature along the sealing bars or belts.

- Conveyor System: A built-in conveyor moves the product through the sealing area.

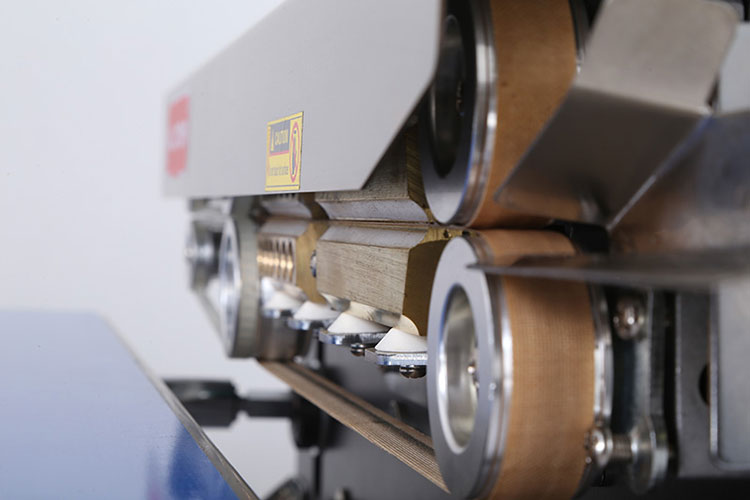

- Sealing Process: As the material passes through, the constant heat fuses the plastic, creating a secure seal.

- Cooling and Solidifying: After sealing, the material moves to the cooling section where the seal solidifies.

Key Features of Horizontal Continuous Heat Sealers

- Constant Temperature Control: Ensures consistent sealing quality across different materials and thicknesses.

- Adjustable Conveyor Speed: Allows for control over the sealing speed to match production needs.

- Versatile Sealing Capabilities: Suitable for a variety of materials including polyethylene (PE), polypropylene (PP), and laminated films.

- Integrated Cooling System: Helps to quickly solidify the seal, ensuring durability and strength.

- Automation: Reduces manual labor and increases production efficiency.

Types of Horizontal Continuous Heat Sealers

- Standard Horizontal Continuous Heat Sealers: Basic models designed for general sealing tasks.

- Heavy-Duty Horizontal Continuous Heat Sealers: Built for more demanding industrial applications, with enhanced durability and higher throughput.

- Specialized Horizontal Continuous Heat Sealers: Equipped with additional features such as printing capabilities for coding and labeling during the sealing process.

Applications of Horizontal Continuous Heat Sealers

- Food Packaging: Sealing bags of snacks, frozen foods, and perishable items to ensure freshness.

- Pharmaceuticals: Packaging medicines and medical supplies in sterile, tamper-evident packaging.

- Retail Products: Sealing various consumer goods such as clothing, electronics, and toys.

- Industrial Components: Packaging hardware, tools, and other small parts for shipment.

- Chemical Products: Sealing bags of powders, granules, and other chemical substances.

Benefits of Using Horizontal Continuous Heat Sealers

- High Efficiency: Capable of sealing a large number of packages quickly, making them ideal for high-volume operations.

- Consistent Quality: Maintains uniform sealing quality due to constant temperature control.

- Versatility: Can handle a wide range of materials and packaging sizes.

- Automation: Reduces the need for manual intervention, lowering labor costs and minimizing human error.

- Durability: Provides strong, reliable seals that enhance the shelf life and integrity of packaged products.

How to Choose the Right Horizontal Continuous Heat Sealer

When selecting a horizontal continuous heat sealer, consider the following factors:

- Material Compatibility: Ensure the machine can handle the types of materials you use.

- Sealing Speed: Choose a sealer with an adjustable speed to match your production requirements.

- Conveyor Size: Make sure the conveyor is wide enough to accommodate your largest packages.

- Temperature Range: Select a sealer with an appropriate temperature range for your materials.

- Additional Features: Look for models with extra features like printing capabilities if needed.

Maintenance and Care Tips

- Regular Cleaning: Keep the sealing bars and conveyor system clean to prevent residue build-up and ensure consistent sealing.

- Routine Inspections: Check the heating elements and temperature controls regularly to ensure they are functioning correctly.

- Proper Lubrication: Lubricate moving parts as recommended by the manufacturer to maintain smooth operation.

- Replace Worn Parts: Periodically replace worn belts, Teflon strips, and other components to maintain optimal performance.

- Calibration: Regularly calibrate the temperature control system to ensure accurate sealing temperatures.

Conclusion

Horizontal continuous heat sealers are indispensable for businesses that require efficient, high-speed packaging solutions. Their ability to provide consistent, high-quality seals while accommodating a wide range of materials makes them ideal for various industries, from food packaging to pharmaceuticals and retail. By understanding their functionality, features, and maintenance needs, you can leverage these machines to enhance your packaging operations, increase productivity, and ensure the integrity of your products.

Investing in a high-quality horizontal continuous heat sealer can transform your packaging process, offering speed, reliability, and versatility that meet the demands of modern production environments. Whether you’re sealing food products, industrial components, or consumer goods, these machines provide a robust solution to keep your items securely packaged and ready for market.