Vacuum Sealers in Modern Packaging

Introduction:

In the quest for preserving freshness and extending shelf life, vacuum sealers emerge as a formidable solution in the world of packaging. These machines harness the power of vacuum technology to remove air from packaging, creating an airtight seal that safeguards products from spoilage, oxidation, and freezer burn. In this comprehensive blog, we’ll explore the versatility, benefits, and applications of vacuum sealers, shedding light on their indispensable role in modern packaging operations.

Understanding Vacuum Sealers:

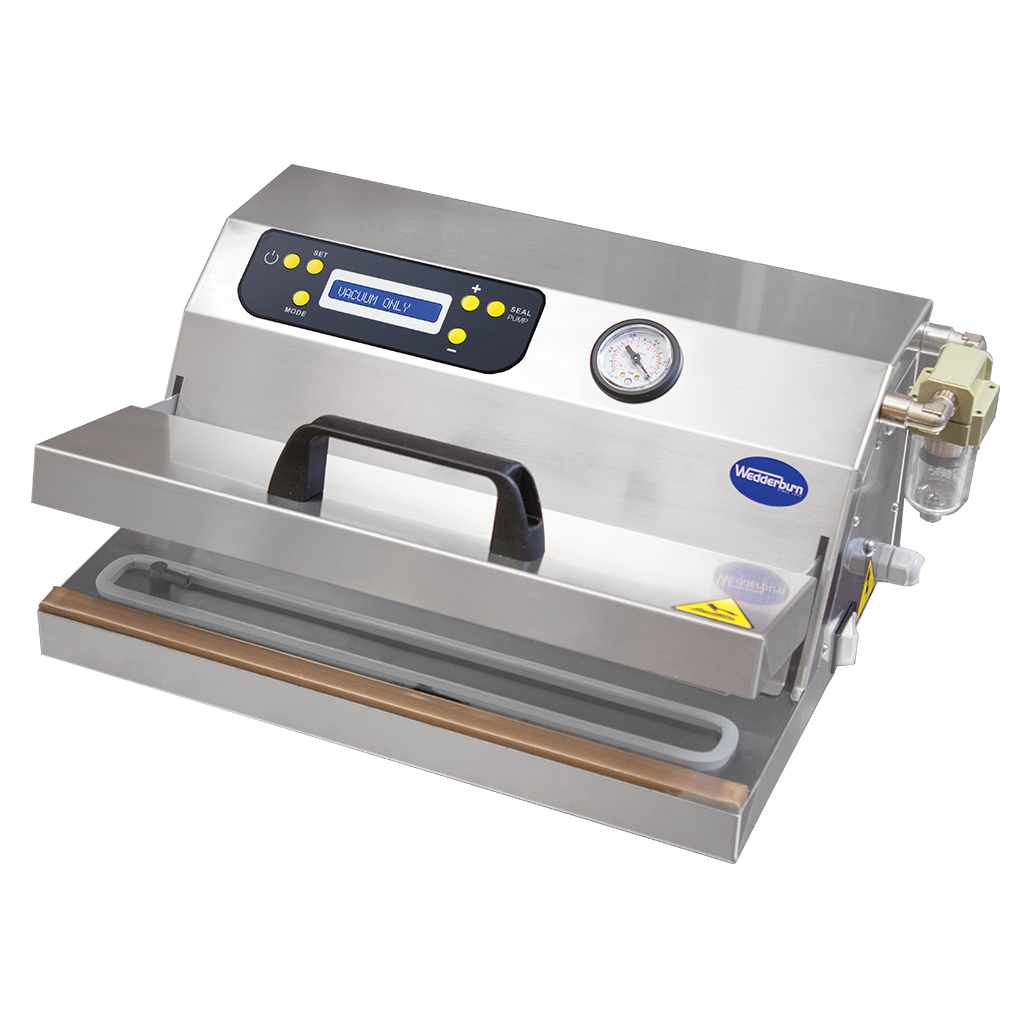

Vacuum sealers are packaging machines designed to remove air from packaging before sealing, creating a vacuum environment that helps preserve the freshness and quality of the contents. They utilize vacuum technology to extract air from the package, followed by heat sealing to create a secure barrier that protects the contents from external elements such as moisture, bacteria, and odors.

How Vacuum Sealers Work:

The operation of vacuum sealers is straightforward yet highly effective. The packaging material, typically a vacuum bag or pouch, is placed in the machine’s chamber. The air is then evacuated from the chamber, creating a vacuum environment around the package. Once the desired level of vacuum is achieved, the machine seals the package, creating an airtight barrier that locks in freshness and flavor. Vacuum sealers may also incorporate additional features such as gas flushing, which replaces the extracted air with inert gases like nitrogen to further extend shelf life.

Types of Vacuum Sealers:

Vacuum sealers come in various configurations to accommodate different packaging needs and production volumes. Common types include:

- Chamber Vacuum Sealers:Chamber vacuum sealers feature a chamber where both the product and the packaging material are placed. The entire chamber is evacuated of air, creating a vacuum around the package before sealing. Chamber vacuum sealers are versatile machines suitable for sealing a wide range of products, from food items to pharmaceuticals.

- External Vacuum Sealers:External vacuum sealers, also known as nozzle-type sealers, utilize an external vacuum source to remove air from the package. The open end of the packaging material is placed outside the machine, and a vacuum nozzle extracts air from the package before sealing. External vacuum sealers are commonly used for sealing bags and pouches in home kitchens, small businesses, and retail environments.

- Single Chamber Vacuum Sealers:Single chamber vacuum sealers feature a single vacuum chamber where the packaging material is placed for sealing. These compact machines are ideal for small-scale packaging operations and are commonly used in home kitchens, delis, and small food businesses.

- Double Chamber Vacuum Sealers:Double chamber vacuum sealers feature two vacuum chambers that operate alternately, allowing for continuous sealing without the need to wait for the vacuum cycle to complete. These machines are suitable for high-volume packaging operations and are commonly found in commercial kitchens, food processing facilities, and large-scale manufacturing operations.

Applications of Vacuum Sealers:

Vacuum sealers find applications across a wide range of industries and packaging scenarios, including:

- Food Packaging: Vacuum sealers are widely used in the food industry for packaging perishable items such as meat, poultry, fish, cheese, and vegetables. They help extend the shelf life of food products by removing air and reducing oxygen exposure, preventing spoilage and freezer burn.

- Pharmaceutical Packaging: In the pharmaceutical sector, vacuum sealers are employed to package medications, medical devices, and diagnostic kits securely. They create a sterile environment that protects sensitive products from contamination and ensures product integrity.

- Industrial Packaging: Vacuum sealers are used in industrial settings for packaging electronics, hardware, and industrial components. They provide a protective barrier that safeguards delicate components from moisture, dust, and damage during shipping and storage.

- Household Use: Vacuum sealers are also popular for home use, allowing consumers to vacuum-seal food items for long-term storage in the freezer or pantry. They help reduce food waste by preserving the freshness and flavor of leftovers, bulk purchases, and garden harvests.

Benefits of Vacuum Sealers:

- Extended Shelf Life: Vacuum sealers help extend the shelf life of perishable products by removing air and reducing oxygen exposure, preventing spoilage and freezer burn.

- Preservation of Freshness and Flavor: Vacuum sealing locks in freshness, flavor, and nutritional value, ensuring that products retain their quality over time.

- Improved Hygiene and Safety: Vacuum sealing creates a sterile environment that protects products from contamination and ensures product safety and integrity.

- Efficient Storage and Transportation: Vacuum-sealed packages are compact and airtight, making them easier to store, stack, and transport, thereby optimizing space and reducing shipping costs.

- Reduced Food Waste: Vacuum sealing helps reduce food waste by prolonging the shelf life of perishable items and preventing spoilage and freezer burn.

Conclusion:

Vacuum sealers are indispensable tools in modern packaging operations, offering efficiency, reliability, and versatility across diverse industries. Whether sealing food products, pharmaceuticals, electronics, or industrial components, these machines play a crucial role in preserving freshness, extending shelf life, and ensuring product integrity. As technology continues to advance, vacuum sealers will remain essential components of the packaging arsenal, providing innovative solutions to meet the evolving needs of the packaging industry.